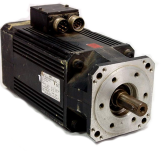

Servo Motors, DC Motors, Brush-less Motors & more

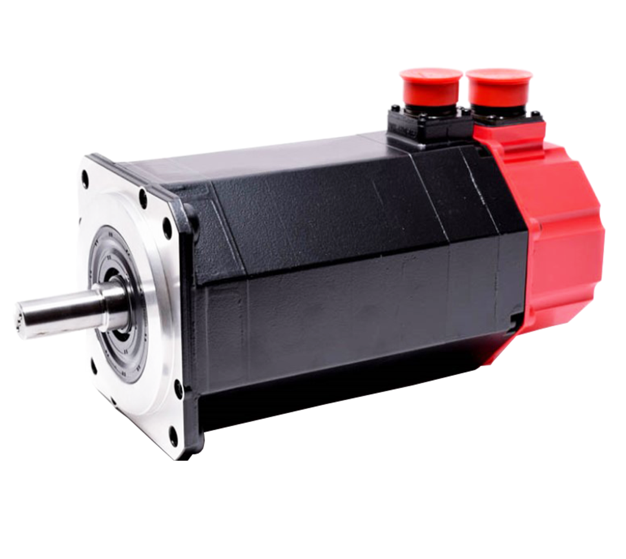

Industrial servo motors are available in a broad range of sizes and types.These motors can be constructed for either AC or DC power sources, and they can be designed with a variety of base RPM and maximum RPM speeds.

For precise control, AC Servo Motors are coupled with an encoder or a resolver whereas DC motorstypically have tachometer feedback control. Industrial Servo Motors can be used to position ball screws, as well as to operate a broad variety of geared devices, including grinders and cutters of all sizes.

AC Servo Motors

Servo motors are variable position electrical motors that control the action of a mechanical device in a servo mechanism. Industrial servo motors are available in a broad range of sizes and types. An AC motor is an electric motor driven by an alternating current. AC servo motors will typically be coupled with an encoder for precise control. They can be used to position ball screws, as well as a variety of geared devices.

There are two main types of AC motors, depending on the type of rotor used. The first type is the induction motor, which runs slightly slower than the supply frequency. The second type is the synchronous motor, which does not rely on induction and, as a result, can rotate exactly at the supply frequency or a sub-multiple of the supply frequency. The magnetic field on the rotor is either generated by current delivered through slip rings or by a permanent magnet.

Other types of motors include eddy current motors, and also AC/DC mechanically commutated machines, in which speed is dependent on voltage and winding connection.

AC servo motors can be extremely reliable, but, when they fail, you can rely on AxxA's qualified technicians to get them back to top working order again quickly, reducing your down-time and lowering the overall cost of your repair dramatically.

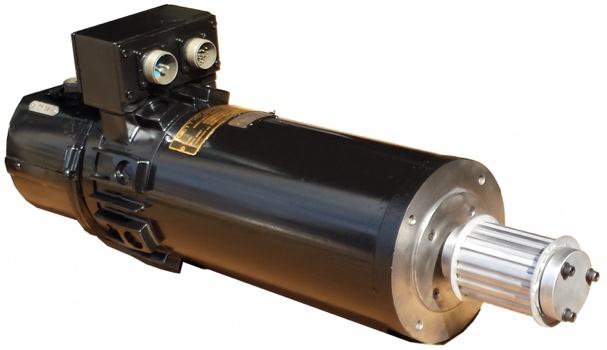

AC Spindle Motors

Industrial servo motors come in a broad range of sizes and types. AC motors will typically be coupled with an encoder for precise control. They can be used to position ball screws, as well as operating a variety of geared devices. Spindle Motors are V3 class low vibration 3 phase induction AC motors. They offer extra low vibration performance and they are specifically designed for grinding machines and low-vibration applications. They are available in sizes from 1HP to 10HP.

The high-peak-torque capability of a high-performance AC spindle motor, combined with its low rotor inertia, enables higher acceleration rate-to-base speeds than are available with a standard AC motor. The general laws of physics determine the required torque values to accelerate and decelerate loads powered by spindle motors.

For applications that require higher maximum speeds, some spindle motors have a wye-delta winding selection option. This extends the spindle motor’s constant-horsepower maximum speed without mechanical gear changes.

When your AC spindle motor needs repair, your company’s operation can suffer – unless you send them to AxxA's. Our fully experienced, qualified technicians will get them back to top performance capability and back in your hands in record time.

DC Servo Motors

Servo motors are variable position electrical motors.

They control the action of the mechanical device in a servo mechanism and are vital to the proper operation of a wide array of industrial process equipment.

Industrial servo motors range in both size and type. For example, motors can be constructed for either AC or DC power sources, designed with a variety of base RPM and maximum RPM speeds. DC motors typically have tachometer feedback control, whereas AC motors will typically be coupled with an encoder, for precise control. They can be used to position ball screws, as well as a variety of geared devices.

Today, DC motors are still found in applications as small as toys and disk drives, or in large sizes, to operate steel rolling mills and paper machines. Modern DC motors are nearly always operated in conjunction with electronic devices. Two important performance parameters of DC motors are the motor constants: Kv and Km.

Brushed

The brushed DC electric motor generates torque directly from DC power supplied to the motor by using internal commutation, stationary magnets (permanent or electromagnets), and rotating electrical magnets.

Brushless

Brushless DC motors use a rotating permanent magnet or soft magnetic core in the rotor, and stationary electrical magnets on the motor housing. A motor controller converts DC to AC. This design is simpler than that of brushed motors because it eliminates the complication of transferring power from outside the motor to the spinning rotor. Some brushless motors are referred to as "synchronous motors," although they have no external power supply to be synchronized with, as would be the case with normal AC synchronous motors.

Axxa’s highly qualified and experienced technicians can handle all your industrial servo motor repair needs.

Axxa has a state-of-the-art Servo Motor Repair facility, including an amazing array of live bench-testing capabilities, to ensure repairs are done to perfection to meet or exceed OEM specifications.

Finding the right repair company can be tricky. However, with our in-house repair and testing capabilities, we make every effort to make sure that Servo Motor Repair is the cost-effective choice over replacement. Commitment to superior customer service and getting our client's facilities back up and running as quickly as possible are the hallmarks of our work philosophy. We are aware that reducing downtime and minimizing disruptions to production schedules is very critical to any business. We, therefore, offer to optimize your solutions by helping you prevent servo motor disruptions. When your servo motor goes down, the repair services team from Axxa is always ready to help you.

Please use due diligence and take some time to request a quote or you can give us a call at (716) 270-0047 to discuss all of your repair options. Standard repair are No Bench Fee and all repairs are augmented by our ‘No Fix No Fee’ commitment. All Servo Motor Repairs and sales are warranted for one year.

TOP 5 REASONS MOTORS FAIL:

- Lack of Maintenance

- Bad Windings

- Poor Voltage

- Cracked Seals

- Dry Bearings

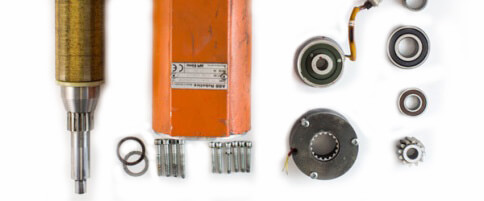

Repair Procedures:

- As and when your servo motor needs repairs, simply ship it to us and we will respond with a repair quote within two working days. Once you approve the quote, our trained technicians begin repair work on your servo motor immediately. Each servo motor repair goes through a step by step repair process: -

- First step in repair process begins with a visual inspection and continues as our technicians rotate the shaft, both forward and reverse, and meg the motor and perform Hypot test.

- The next step is the putting the servo motor through test bench equipment where the alignment of the feedback is checked, KE test is performed, and the functioning of feedbacks including resolver angles, encoder count and tach voltages are checked.

- Servo motor is then disassembled, cleaned and baked, the surge and hi-pot test are performed, and our technicians check for machine work. In this stage of repair process, we, rewind the windings, install new bearings and seals, replace damaged connectors, replace machine pilot, shaft and mounting areas where needed.

- The repaired servo motor is now ready for reassembly, feedback is aligned and bench test is performed with our test equipment. The repaired Servo Motor is also run on a system drive at this stage to it works perfectly when received and installed by the customer.

The servo motor test consists of:

- Measurement / Winding Resistance Test

- Magnetization test

- Motor torque test when stopped

- Brake test

- Response test using various models of encoders

- Shaft Run Test

- Complete test of motor under load

- Finally, we tape and paint your repaired servo motor prior shipping it back to your facility.

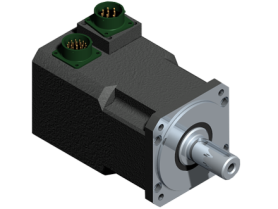

Servo Motor Feedback Repairs

Feedback devices are the communication devices mounted on servo motor shafts that send information back to the control about speed, direction of rotation, position, acceleration/ deceleration rate, and the relative position of the rotor to the stator.

Read More

Absolute Encoder

It has many code rings with different binary weightings which provides a digital data word representing the absolute position of the encoder within one revolution down to the precision of the least significant bit. Adding more bits will divide one revolution into smaller segments, and the encoder will, therefore, provide higher resolution.

Read more

Serial Encoders

These transfer their information to the control electronics in serial data stream. Serial data provides transmission of the data one bit after the other instead all at once. Serial Encoders are checked by a computerized serial interface, accurate count checks are done with special Pulse Counting Gadgets.

Read more

Servo Motor Brake Repairs

Brakes used on servo motors are very critical because they not only are expected to perform the function of stopping and holding the rotor, but also could be a safety concern if they fail to operate properly. Brakes should be replaced if the are worn out considerably at the time of repair. Axxa has the capability to customize variants of spring-applied and electromagnetic brakes for servo motors. Additionally, we also stock brakes for leading servo motor manufacturers.

- Spring-Type Brake- Used without electricity springs against a pressure plate, squeezing both the inner and outer plate. The clamping force is transferred to the hub which is connected to the shaft.

- Electromagnetic Brake- stops and holds a load when electrical power is disconnected. Additional disks can be used to increase torque without changing the size of the brake.

ABB Servo Motor Repair

- ABB 3HAB Series Servo Motor Repair

- ABB 3HAC Series Servo Motor Repair

- ABB 3HNM Series Servo Motor Repair

- ABB 8C Series Servo Motor Repair

- ABB 9C Series Servo Motor Repair

- ABB CHSeries Servo Motor Repair

- ABB CMSeries Servo Motor Repair

ALLEN BRADLEY Servo Motor Repair

- Allen Bradley MP Series Servo Motor Repair

- Allen Bradley MPL Series Servo Motor Repair

- Allen Bradley MPF Series Servo Motor Repair

- Allen Bradley MPF-A Series Servo Motor Repair

ALLEN BRADLEY (Electrocraft, Reliance Electric and Elwood Getty) Servo Motor Repair

- Allen Bradley 1326AD Series Servo Motor Repair

- Allen Bradley 1326AB Series Servo Motor Repair

- Allen Bradley N Series Servo Motor Repair

AEROTECH Servo Motor Repair

- Aerotech 10 Series Servo Motor Repair

- Aerotech 12 Series Servo Motor Repair

- Aerotech 15 Series Servo Motor Repair

ANAHEIM Servo Motor Repair

- Anaheim EMG Series Servo Motor Repair

- Anaheim EMJ Series Servo Motor Repair

- Anaheim EML Series Servo Motor Repair

- Anaheim KNC-SRV Series Servo Motor Repair

ATLAS COPCO Servo Motor Repair

- Atlas Copco AHD Series Servo Motor Repair

- Atlas Copco BSM Series Servo Motor Repair

- Atlas Copco EP Series Servo Motor Repair

B&R Servo Motor Repair

- B&R 8MSA Series Servo Motor Repair

- B&R 8LSA Series Servo Motor Repair

- B&R 8LSA45 Series Servo Motor Repair

BAUMULLER Servo Motor Repair

- Baumuller DS Series Servo Motor Repair

- Baumuller DSC Series Servo Motor Repair

- Baumuller DSD Series Servo Motor Repair

- Baumuller DS0G Series Servo Motor Repair

BALDOR Servo Motor Repair

- Baldor BSM Series Servo Motor Repair

- Baldor BSM N – Series Servo Motor Repair

- Baldor BSM A – Series Servo Motor Repair

BERGER LAHR Servo Motor Repair

- Berger Lahr DSM Series Servo Motor Repair

- Berger Lahr IFA Series Servo Motor Repair

- Berger Lahr IFE Series Servo Motor Repair

BAUTZ Servo Motor Repair

- M Series AC Servo Motor Repair

- F Series AC Servo Motor Repair

- W Series AC Servo Motor Repair

CONTROL TECHNIQUES Servo Motor Repair

- Control Techniques 055E Series Servo Motor Repair

- Control Techniques 055U Series Servo Motor Repair

- Control Techniques 075E Series Servo Motor Repair

- Control Techniques 075U Series Servo Motor Repair

- Control Techniques 095E Series Servo Motor Repair

- Control Techniques 095U Series Servo Motor Repair

- Control Techniques 115E Series Servo Motor Repair

- Control Techniques 115U Series Servo Motor Repair

DANAHAR MOTION Servo Motor Repair

- Danahar Motion CTM Series Servo Motor Repair

- Danahar Motion CTP Series Servo Motor Repair

ELAU Servo Motor Repair

- ElauiSH Series Servo Motor Repair

- ElauSH Series Servo Motor Repair

- ElauSB Series Servo Motor Repair

- ElauSB 70 Series Servo Motor Repair

ELECTRO-CRAFT (RELIANCE) Servo Motor Repair

- Electro-Craft F Series Servo Motor Repair

- Electro-Craft H Series Servo Motor Repair

ELMO Servo Motor Repair

- Elmo APM Series Servo Motor Repair

- Elmo ABB Robotic Series Servo Motor Repair

EMERSON Servo Motor Repair

- Emerson NT Series Servo Motor Repair

- Emerson MG Series Servo Motor Repair

- Emerson Unimotor Servo Motor Repair

ELWOOD GETTY (Gould) Servo Motor Repair

- Elwood Getty 120 Series Servo Motor Repair

- Elwood GettyR Series Servo Motor Repair

- Elwood Getty S Series Servo Motor Repair

EUROTHERM Servo Motor Repair

- EurothermACG Series Servo Motor Repair

- EurothermACH Series Servo Motor Repair

EXLAR Servo Motor Repair

- ExlarGSM Series Servo Motor Repair

- ExlarSLG Series Servo Motor Repair

- ExlarSLM Series Servo Motor Repair

FANUC GE FANUC Servo Motor Repair

- Fanuc Alpha α Series Servo Motor Repair

- Fanuc Alpha αί Series Servo Motor Repair

- Fanuc Alpha αίs Series Servo Motor Repair

- Fanuc Alpha α(HV)ί Series Servo Motor Repair

FUJI ELECTRIC Servo Motor Repair

- Fuji Electric GYA Series Servo Motor Repair

- Fuji Electric GYC Series Servo Motor Repair

GEC PARVEX Servo Motor Repair

- Gec Parvex HD Series Servo Motor Repair

- Gec Parvex HS Series Servo Motor Repair

- Gec Parvex LD Series Servo Motor Repair

GETTYS Servo Motor Repair

- Gettys SW-Series - Wash Down Servomotor Repair

- Gettys SF-Series - Food Grade Servomotor Repair

- Gettys SP-Series - Plated Servomotor Repair

GIDDINGS & LEWIS Servo Motor Repair

- Giddings & Lewis FSM Series Servo Motor Repair

- Giddings & Lewis HSM Series Servo Motor Repair

GIORDANO COLOMBO Spindle Motor Repair

- Colombo RA Series Spindle Motor Repair

- Colombo RC Series Spindle Motor Repair